Why Micro Warehouses Are Revolutionizing Modern Commerce

A micro warehouse is a small-scale storage facility, typically 3,000 to 10,000 square feet, strategically located near customers to enable same-day or next-day delivery. These compact fulfillment centers are changing how businesses handle inventory and serve their customers.

Quick Facts About Micro Warehouses:

– Size: 3,000-10,000 sq ft (vs. 300,000+ sq ft traditional warehouses)

– Purpose: Enable same-day delivery and reduce last-mile costs

– Market Growth: Expected to reach $15.2 billion by 2030 with 24.3% annual growth

– Cost Savings: Can cut order fulfillment costs by up to 75%

– Inventory: Hold 24-48 hours of fast-moving stock

The explosion of e-commerce has created impossible expectations. Customers want their orders now – not next week, not tomorrow, but today. Traditional warehouses sitting on the outskirts of cities simply can’t deliver on this promise without burning through profits on shipping costs.

Last-mile delivery represents 41% of total supply chain costs, making it the most expensive part of getting products to customers. That’s where micro warehouses step in as game-changers.

These tiny facilities are popping up in urban centers, converted retail spaces, and even corporate complexes. They’re helping businesses slash delivery times while cutting costs – a combination that seemed impossible just a few years ago.

I’m Sam Zoldock, a commercial real estate investment professional who specializes in Alabama markets and has seen how micro warehouse concepts are reshaping business needs. Through my work with flexible commercial spaces, I’ve helped numerous businesses find adaptable solutions that support rapid scaling without the burden of long-term commitments.

Reading Map for This Guide

This comprehensive guide covers:

- What micro warehouses are and why they’re disrupting traditional logistics

- Key benefits and challenges you need to consider

- Implementation strategies that actually work

- Cost comparisons with traditional distribution methods

- Real-world applications across different industries

Whether you’re an e-commerce startup, established retailer, or service provider looking to improve your logistics, this guide will give you the insights you need to make informed decisions about micro warehousing.

What Is Micro Warehousing and Why It Matters

Think of micro warehousing as the neighborhood convenience store version of logistics. Instead of driving 30 minutes to a massive supermarket (traditional warehouse), you pop into the corner shop that has exactly what you need, right when you need it.

This shift from centralized to decentralized inventory management is reshaping how smart businesses think about getting products to customers. Rather than storing everything in one giant facility on the outskirts of town, you’re spreading smaller amounts of your hottest-selling items across multiple urban spots where your customers actually live and work.

With online sales racing toward $9.6 trillion by 2027, the old way of doing things just isn’t cutting it anymore. Customers have gotten used to Amazon’s lightning-fast delivery, and now everyone expects their orders yesterday.

The beauty of micro warehousing lies in solving what seemed impossible – getting faster while spending less. Traditional logistics said you had to pick one or the other. Micro warehouses said “hold my coffee” and delivered both.

Micro Warehouse 101: Definition & Scope

A micro warehouse flips the warehouse game on its head. Instead of building bigger, these facilities go smaller and smarter. We’re talking about spaces between 3,000 to 10,000 square feet – about the size of a decent-sized retail store, not those airplane hangar-sized distribution centers.

What makes these compact powerhouses work isn’t their size, but their strategic placement. They’re tucked into urban areas where people actually live, shop, and need stuff delivered. Think converted retail spaces, repurposed buildings, or purpose-built facilities in dense neighborhoods.

The secret sauce is in what they don’t try to do. A micro warehouse doesn’t attempt to stock everything under the sun. Instead, it focuses on velocity over variety – keeping just the right amount of fast-moving products that local customers want most.

Micro-Fulfillment Center Operation

Micro-fulfillment centers are like the Navy SEALs of the warehouse world – small, highly trained, and incredibly efficient. Many operate as “dark stores” – spaces that look like retail stores but are actually fulfillment machines with no customers walking the aisles.

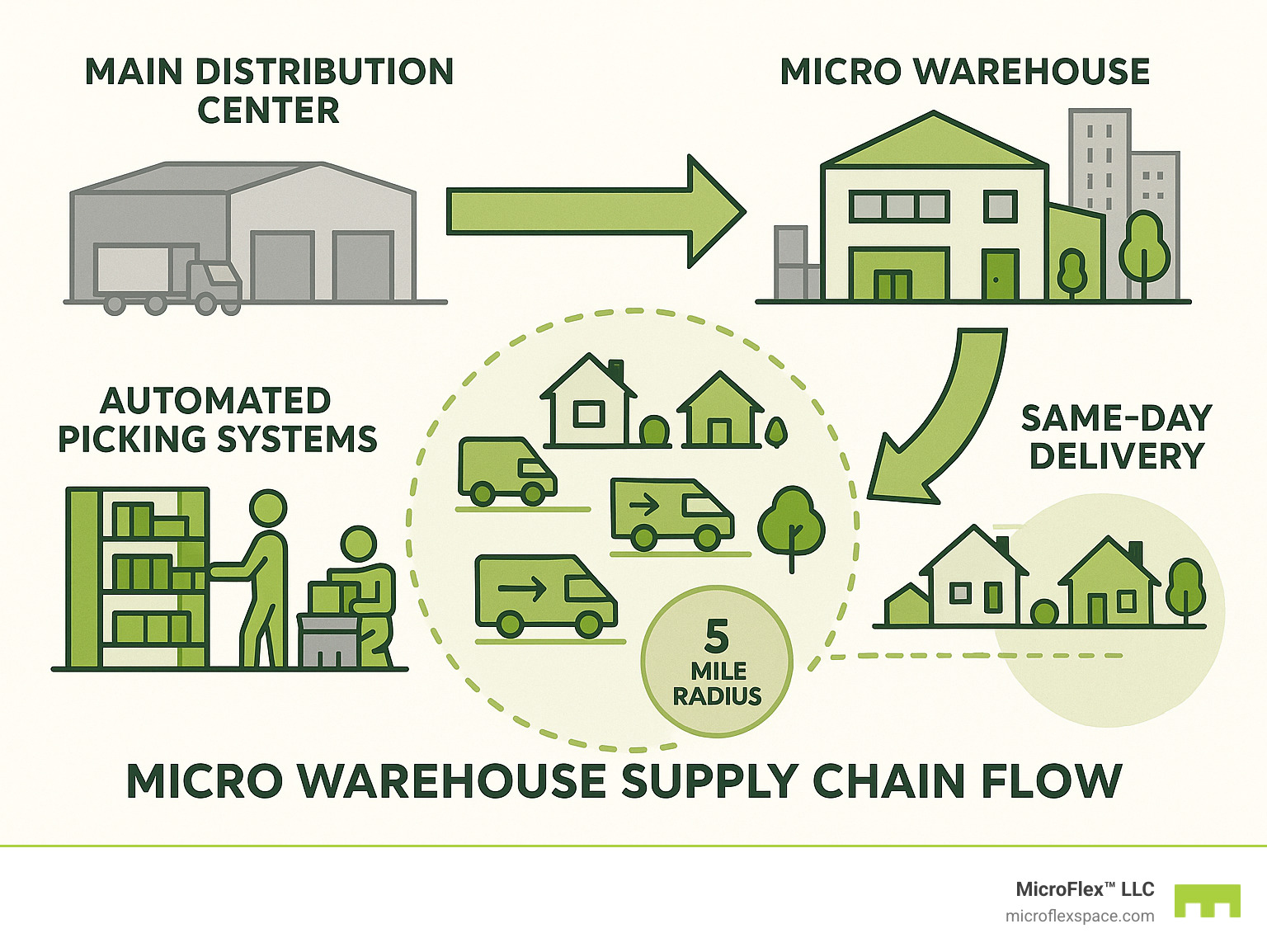

The daily rhythm involves fresh inventory rolling in from regional distribution centers through scheduled delivery runs. These “milk runs” happen multiple times a day because these facilities deliberately keep only 24-48 hours of fast-moving stock on hand.

Once products arrive, automated systems take over the heavy lifting. When orders come in, the fast picking process kicks into high gear. Whether it’s robots zipping around or humans following optimized routes, everything is designed for speed. The goal is to get from “order placed” to “package ready” in minutes, not hours.

According to scientific research on last-mile costs, this hub-and-spoke model is what makes the whole system financially viable by dramatically cutting that expensive final mile of delivery.

Micro Warehouse vs. Traditional Distribution Centers

When you compare a micro warehouse to a traditional distribution center, you’re looking at two completely different philosophies. It’s like comparing a corner coffee shop to a massive grocery store – both serve food and drinks, but the experience and economics are worlds apart.

Traditional distribution centers were built for a different era. These massive facilities, often exceeding 300,000 square feet, sit on cheap land outside cities where rent is low. They’re designed to hold months of inventory and ship products anywhere within a region.

Micro warehouses flip this model on its head. At just 3,000 to 10,000 square feet, they’re tiny by comparison. But what they lack in size, they make up for in speed and proximity to customers.

| Factor | Micro Warehouse | Traditional DC |

|---|---|---|

| Size | 3,000-10,000 sq ft | 300,000+ sq ft |

| Location | Urban, near customers | Suburban/rural, cheap land |

| Inventory | 24-48 hours of stock | Weeks/months of inventory |

| Delivery Time | Same-day/next-day | 2-7 days |

| Cost per Order | $4-7 | $15-25 |

| Inventory Turns | 8-10 times/year | 1-2 times/year |

| Setup Time | Weeks | Months/years |

| Lease Flexibility | High | Low |

The cost per order difference is striking. While traditional warehouses struggle with expensive last-mile delivery, micro warehouses cut those costs dramatically by starting closer to the customer. That $15-25 per order from a traditional DC drops to $4-7 when you’re shipping from just a few miles away.

Scalability of a Micro Warehouse Network

The beauty of micro warehouse networks lies in their modular approach. Think of them as building blocks – you start with one and add more as your business grows. This is completely different from traditional warehousing, where you typically make one big bet on a massive facility.

Starting small gives you incredible flexibility. You can test new markets with minimal risk, scale up gradually based on real demand, and pivot quickly when customer patterns change. If a location doesn’t work out, you’re not stuck with a massive lease or facility.

This modular approach works especially well for businesses that are still figuring out their optimal footprint. The physical spaces themselves offer remarkable flexibility. Some businesses convert old retail stores, others share space in existing facilities, and many use seasonal pop-up locations during peak periods. This is where Short Term Warehouse Rental options become game-changers, letting you experiment without long-term commitments.

Benefits That Make Micro Warehousing Irresistible

The business world is full of “revolutionary” ideas that fizzle out. But micro warehouse operations are different. They’re delivering real results that you can measure in both dollars and customer smiles.

When your inventory sits just minutes away from customers instead of hours, everything changes. Faster fulfillment becomes your new superpower, especially when 42% of retailers say it’s their top priority. Same-day delivery stops being a luxury service and becomes an everyday reality.

Reduced last-mile costs aren’t just nice to have – they’re game-changing. Since last-mile delivery gobbles up over 50% of your logistics budget, even a 25% reduction creates serious savings. Some businesses report cutting their order-filling costs by 75% compared to traditional fulfillment methods.

Your customers notice the difference immediately. Improved customer satisfaction follows naturally when you can offer what 79% of consumers actually want: reliable next-day delivery.

The environmental story writes itself. Lower emissions happen automatically when your delivery trucks travel five miles instead of fifty. Many micro warehouse operators can even use electric vehicles or bicycles for final delivery.

Business Advantages

Running a micro warehouse feels completely different from managing a traditional distribution center. The operational benefits start showing up from day one.

Inventory accuracy improves dramatically when you’re tracking 1,000 SKUs instead of 100,000. Faster response to demand changes becomes possible when you’re not locked into massive inventory commitments. Reduced risk through diversification means a disruption at one location doesn’t shut down your entire operation.

Automation ROI finally makes sense at smaller scales. While full warehouse automation might require millions in investment, micro warehouse systems can be implemented for hundreds of thousands. The payback period shrinks from years to months.

This is exactly why businesses are exploring Mini Warehouse Storage options – they need the flexibility to test automated systems without betting the farm on unproven technology.

Consumer & Sustainability Wins

The environmental benefits extend far beyond shorter delivery routes. The entire micro warehouse model supports more sustainable commerce in ways that matter to today’s conscious consumers.

Reduced packaging waste happens naturally through consolidated shipments to micro locations. Electric vehicle viability becomes realistic for short urban routes. Decreased urban congestion results from optimized delivery patterns that actually make sense for city streets.

The real magic happens in the new service models that micro warehouses enable. Flexible pickup options from convenient urban locations give customers alternatives to home delivery. Emergency fulfillment for urgent needs turns into a competitive advantage. Personalized inventory based on local preferences means your Chicago location can stock different items than your Miami facility.

These aren’t just nice features – they’re becoming customer expectations.

Challenges & Strategic Considerations

If micro warehousing were easy, everyone would already be doing it. While the benefits are compelling, there are real challenges you need to understand before diving in.

The biggest hurdle? Higher replenishment frequency. Unlike traditional warehouses where you might restock weekly, micro warehouses need fresh inventory almost daily. It’s like keeping a convenience store stocked versus a warehouse club.

Coordination complexity grows exponentially with each new location. Managing one large warehouse is like conducting a small orchestra. Managing ten micro warehouses? That’s like conducting ten different bands playing different songs at the same time.

The financial reality is that operational costs per square foot will be higher than traditional warehouses. Small facilities simply can’t achieve the same economies of scale. Technology investment requirements are significant and non-negotiable. Micro warehouses depend on sophisticated inventory management systems and automation to work efficiently.

Zoning and regulatory challenges can be tricky. Converting that perfect retail space into a micro warehouse might sound simple, but urban zoning laws, permit processes, parking requirements, and noise restrictions all come into play.

Risk Management for Micro Warehouse Sites

The distributed nature of micro warehouse networks creates unique challenges you wouldn’t face with a single large facility.

Localized disruptions can knock out service to entire neighborhoods. A water main break, power outage, or even a fender-bender blocking your loading dock can leave customers in that area without service.

Demand spikes become trickier to handle when your inventory is spread thin across multiple locations. Security concerns multiply with more locations. Quality control requires extra attention when operations are distributed.

Tech Stack & Automation Essentials

Success in micro warehousing isn’t just about having the right space – it’s about having the right technology to make that space work efficiently.

Your warehouse management system (WMS) needs to handle multiple locations with real-time inventory visibility and automated replenishment triggers. Robotics and automation scaled for smaller facilities can include automated storage systems, picking robots, or conveyor systems designed for compact spaces.

Demand forecasting tools must predict inventory needs at the micro-location level. Integration platforms connect your micro warehouse network with e-commerce platforms, transportation management systems, and customer communication tools.

According to scientific research on micro warehousing, technology investment typically represents 30-40% of total setup costs. Without proper tech infrastructure, you’re just running expensive small warehouses instead of an efficient micro warehouse network.

Last-Mile Impact: How Micro Warehouses Transform Urban Logistics

Urban logistics is expensive – really expensive. Last-mile delivery costs eat up 41% of your total supply chain budget, making it the single most costly part of getting products to customers. That’s where micro warehouse facilities become absolute game-changers.

Think about traditional delivery. Your package starts at a massive warehouse 50 miles outside the city, gets loaded onto a truck that fights through traffic, burns fuel in stop-and-go congestion, and finally reaches your door hours later.

Micro warehouses completely flip this expensive model. Instead of those grueling 50-mile journeys from suburban facilities, your products start just 5 miles away from customers. This proximity creates immediate benefits that show up directly in your profit margins.

Fuel consumption per delivery drops dramatically. Driver productivity skyrockets because they’re completing deliveries instead of sitting in traffic. Route optimization becomes incredibly powerful with shorter distances. A single delivery vehicle can complete multiple routes in the same day.

Electric vehicles suddenly make perfect sense for these short urban routes. The range limitations that make electric delivery trucks impractical for long hauls become irrelevant when your furthest customer is just a few miles away.

Scaling a Micro Warehouse Network for Same-Day Reach

Building a micro warehouse network that actually delivers same-day service requires thinking like a strategist. You’re essentially creating overlapping coverage zones where every customer falls within easy reach of at least one facility.

The hub-and-spoke model becomes your operational backbone. Your main distribution center acts as the hub, feeding multiple micro warehouse locations through carefully scheduled delivery runs. These “milk runs” create predictable patterns that keep your small facilities stocked.

Demand forecasting at the micro level means predicting exactly which location customers will order from. This involves analyzing historical patterns for each specific area, understanding how seasonal changes affect different neighborhoods, and tracking local events that might spike demand.

Getting your milk run schedules right is crucial. Run them too frequently, and transportation costs kill your savings. Run them too infrequently, and you’ll face empty shelves when customers want to order. The sweet spot usually involves 2-3 scheduled deliveries per day to each micro location.

This is where flexible space solutions like Central Alabama Small Warehouse Rental become invaluable. You can test different coverage areas and demand patterns without getting locked into expensive long-term commitments.

You can start small and grow strategically. Launch with one or two micro warehouse locations, prove the model works in your market, then expand coverage area by area until you’ve built a network that makes same-day delivery profitable.

Is a Micro Warehouse Strategy Right for You?

Micro warehouse operations aren’t a magic solution for every business. They work brilliantly for some companies and can be a costly mistake for others. The key is understanding whether your specific situation aligns with what makes micro warehousing successful.

High-velocity items that fly off the shelves are perfect candidates. Think electronics, fashion accessories, or health products that customers order repeatedly. These items justify the frequent replenishment cycles that micro warehouses require.

If you’re selling custom furniture or specialty industrial equipment that moves once a month, micro warehousing probably isn’t your answer. The model thrives on standardized products that don’t need special handling and have moderate values where shipping costs actually matter.

Your order patterns tell the real story. You need consistent daily volume – typically at least 50-100 orders per day per location to make the economics work. Your customers need to be geographically concentrated. If your orders are scattered randomly across the country, you’re better off with traditional distribution.

The financial reality is straightforward: each micro warehouse location requires $100,000 to $500,000 in technology investment, plus ongoing operational costs that run higher per square foot than traditional warehouses.

Successful micro warehouse operators typically have: consistent daily order volumes exceeding 200 units, customers who cluster in specific areas, current shipping costs above 15% of revenue, and the operational capability to manage multiple locations simultaneously.

For Alabama-based businesses, options like Small Warehouse for Rent Birmingham AL provide perfect testing grounds without massive long-term commitments.

Implementation Roadmap

Rolling out a micro warehouse network involves three distinct phases, each building on lessons learned from the previous stage.

Phase one focuses on analysis and planning (2-3 months). Dig deep into your current shipping costs and delivery patterns. Identify optimal locations for your first micro warehouses and select technology partners. Don’t rush this phase – the planning determines whether your entire network succeeds.

Phase two launches your pilot program (3-6 months). Start with one location in your highest-density market. This facility becomes your testing ground for operational procedures, technology systems, and staffing approaches. Measure everything against your traditional fulfillment methods.

Phase three expands your network (6-12 months). Roll out additional locations based on your pilot results, implement integrated inventory management across all sites, and optimize your replenishment and delivery routes.

Site selection requires balancing customer density within a five-mile radius, good transportation access for replenishment, available labor for operations, and zoning compliance for warehouse use.

Track the right metrics: order fulfillment time, delivery cost per order, inventory turnover rates, customer satisfaction scores, and overall profitability per location.

Funding & Partnership Options

Several approaches can reduce your risk and capital requirements.

In-house development gives you maximum control but demands the highest investment. You’ll need capital for facility leases, technology systems, initial inventory, staffing, and working capital.

Third-party logistics partnerships reduce upfront costs by leveraging existing infrastructure. Many 3PLs now offer micro-fulfillment services on a per-order basis.

Subscription models are emerging where you access micro warehouse services for monthly fees plus per-order charges. Automation leasing allows you to deploy expensive robotic systems without large capital outlays.

The key is matching your funding approach to your risk tolerance and growth timeline.

Frequently Asked Questions about Micro Warehouses

How much inventory should a micro warehouse hold?

The sweet spot for most micro warehouse operations is 24-48 hours of inventory for your fastest-moving products. This usually means stocking between 500-2,000 individual items, depending on what you sell and how quickly orders come in.

Several factors determine your exact inventory levels. Replenishment frequency plays a huge role – if you get daily deliveries from your main warehouse, you can keep less stock on hand. Demand predictability matters too. Your product mix also influences inventory levels. Finally, your service level targets determine how much backup inventory you need.

The key is starting conservative and adjusting based on real performance data. Most businesses find their optimal inventory levels after 2-3 months of operation.

What industries benefit most from micro warehousing?

E-commerce and retail businesses see immediate benefits from faster delivery and lower shipping costs. This works especially well for electronics, clothing, and everyday consumer goods.

Fast-moving consumer goods are perfect candidates because they turn over quickly and come in standard packaging. Think health and beauty products, household supplies, and non-perishable foods.

Automotive parts distribution benefits tremendously because mechanics and car owners often need parts urgently. Pharmaceutical distribution works well for non-controlled medications and medical supplies. Business-to-business suppliers serving urban markets can dramatically reduce delivery costs while improving service levels.

The common thread is high order frequency, predictable demand, and time-sensitive delivery needs.

How long does it take to convert retail space into a micro warehouse?

Converting existing retail space into a micro warehouse typically takes 2-6 weeks, though the exact timeline depends on how much modification the space needs.

The first week or two involves planning and permits. You’ll finalize your space layout, figure out workflow patterns, and get necessary permits and zoning approvals.

Weeks 2-4 cover the physical modifications. This might include installing or modifying loading docks, setting up storage systems and shelving, installing technology infrastructure, and completing safety and security systems.

The final weeks focus on system integration and testing. You’ll configure warehouse management systems, train staff on new procedures, test everything with sample orders, and conduct trial runs before going live.

Spaces that already have appropriate infrastructure convert much faster. Most businesses recover their conversion costs within 6-12 months through improved operational efficiency.

Conclusion

The micro warehouse revolution isn’t coming – it’s already here, and it’s reshaping how smart businesses think about getting products to customers. With the global micro fulfillment market charging ahead at 24.3% annual growth through 2030, the companies jumping in now are the ones who’ll be leaving their competitors in the dust.

Your customers want their stuff fast, cheap, and without harming the planet. Traditional warehouses sitting way out in the suburbs just can’t deliver on all three. But micro warehouses? They’re the sweet spot where speed meets savings meets sustainability.

The math is simple. Businesses that can deliver products faster, cheaper, and more responsibly than their competitors win. Those that can’t become cautionary tales about companies that missed the boat.

You don’t need to bet the farm to test this out. Smart businesses start with pilot programs that let them test the waters without diving headfirst into the deep end. Whether you’re tired of watching shipping costs eat your margins, frustrated with customer complaints about slow delivery, or just want to stay ahead of the curve, micro warehousing offers a real solution.

At MicroFlex™ LLC, we get it. Modern businesses need spaces that can roll with the punches and adapt as they grow. That’s why our flexible lease terms and multi-function spaces are perfect for testing out micro warehouse strategies. From our locations in Auburn Opelika, Birmingham Irondale, Huntsville, and Birmingham Hoover, we’re helping Alabama businesses find what happens when you bring your inventory closer to your customers.

The future of commerce is all about being distributed, flexible, and customer-focused. Micro warehouses aren’t just trendy – they’re the backbone that makes this future work. The only question left is whether your business will be leading this charge or scrambling to catch up later.

Ready to see how micro warehousing could shake things up for your business? Check out our adaptable commercial spaces at Opening Potential: Multi-Use Commercial Properties.

The tiny warehouse revolution is happening right now. It’s time to think big about going small.